| Glass material |

They are the general lighting glass material and the introduction of the production process.

The glass key raw material |

|

|

|

|

|

|

| Basic raw materials of glass |

| Silica Sand |

Silica sand which hits the glass bone material is given to it. Silica is

the raw material which occupies about 70% of the glass formation. |

| Na2CO3 |

The constituent which makes glass easy to melt. About 12%-18 % of the glass formation |

| CaCO3 |

The one for the lime of soda lime glass is given to it. About 3%-12 % of

the glass formation |

| Na2B4O7 |

The durability of the constituent which makes glass easy to melt, and glass

is raised. It becomes the material of hard glass. |

| K2CO3 |

The constituent which makes glass easy to melt. Coloring of the luster on the surface of glass and the color is done, and it becomes the material of leadless Crystal Glass. |

| Al(OH)2 |

The chemical glass durability (acid resistance) is raised. Usually, about

1-2% comes in with soda lime glass with Borosilicate glass (hard glass)

about 3% |

| Feldspar |

Silica, the alumina, Potassium and the sodium are contained, and it is

convenient for taking the foundation constituent . |

| ZnO |

Because the thermal expansion is made comparatively low, it uses for the constituent of Borosilicate Glass. It uses for crystal glass of leadless as well recently. |

| BaCO3 |

The glass raw material of the cathode-ray tube of the television. And,

it uses for crystal glass of optical glass and leadless as well. |

| Others that it oxidizes, carbonic acid lithium, the magnesium oxide and the titanium oxide, the zircon, and so on are used. |

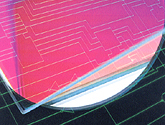

| The production process of the glass product |

| Mixing |

It responds to the use, and the key raw material is mixed. |

↓

| Dissolution |

The raw material made up is made to dissolve with the melting pot in temperature

of about 1,500℃. |

| Shaping |

The glass which dissolved is made the necessary shape. |

|

| The fundamental method of manufacture |

| Blow molding |

Molten glass is involved in the point of the pipe, and the air is blew

into glass like a balloon, and fix it in a mold. |

| Spin molding |

Molten glass is poured into a mold which it turned, and the form is taken with the centrifugal force. |

| Press molding |

Molten glass is poured into the concave mold and pressed by convex shape

mold, and the shape is taken. |

P&B

(Press and Blow) molding |

The method of manufacture that the press & blow blew and molding is

mechanized. |

|

| Annealing |

Molded glass is cooled gradually to take the distortion. The visual inspection

is done after annealing. |

| Processing |

Some of the products need to be cut or holes drilled as final finish. There is also a special processed product. |

|

|

|

| Products Guidance |

|

|

| Research and Development |

|

|

|